Shearing Machine, Presses & Press Brakes

Precision Forming & Cutting Equipment That Powers Industrial Metalworking

At SP Engineers Autotech, we operate a fully equipped metal fabrication facility in Chennai featuring high-performance shearing machines, mechanical/hydraulic presses, and CNC press brakes. These systems form the backbone of our mass production capabilities for automotive, structural, and custom fabrication components.

With over 25 years of experience, our forming and cutting stations are optimized for precision, repeatability, and productivity—enabling us to deliver metal parts in exact shapes, bends, and cuts across a wide range of materials and thicknesses.

Shearing Machine Capabilities

Our hydraulic and mechanical shearing machines are designed for high-speed, clean-edge cutting of metal sheets:

- Capacity: Up to 8mm thick (MS/SS/Aluminum)

- Accuracy: ±0.2mm tolerance for straight and angular cuts

- Output: Smooth, burr-free edges with minimal material waste

- Ideal for: Blank cutting, pre-fabrication, and flat component preparation

- We have CNC Shearing machine capable of cutting up to 10mm thick sheet

Mechanical & Hydraulic Presses

We operate a range of power presses (10–250 tons) for punching, blanking, embossing, and forming tasks:

- Custom tooling for component-specific forming

- Stamping of brackets, supports, washrs, ventilation panels

- Progressive die capability for mass part manufacturing

- Presses operated with safety interlocks and skilled manpower

- We have presses, both pneumatic and hydraulic ranging from 40 tonnes to 400 tonnes with NC COIL FEEDER

Applications include both simple press jobs and compound forming tasks required by auto OEMs and heavy machinery industries.

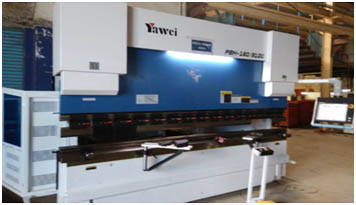

CNC Press Brake Bending Services

Our CNC press brakes deliver high-precision bends, angles, and folds in sheet metal components:

- Length Capacity: Up to 3 meters

- Tonnage: 100 to 250 tons

- Axis: Multi-axis (up to 7-axis) CNC control

- Material Types: MS, SS, Aluminum, GI

- Tolerance: ±0.5° angle precision, ±0.2mm dimensional control

- We have 160 tonned 7axis Press brake to carry out Multiple bends in a single setting

We ensure smooth curves, sharp angles, and perfect repeatability even in high-volume production runs. Our team supports reverse engineering and drawing-based fabrication.

Where We Add Value

- Integrated facility with shearing, pressing, and bending under one roof

- Rapid production cycles for large batches

- In-house tool & die maintenance team

- ISO 9001 & IATF 16949 certified quality control

- CAD/CAM programming for press brake profiles

From flat blanks to precision-formed enclosures and supports, our forming line powers everything from industrial products to automotive structures.

Let’s Shape Success Together

Need clean cuts, sharp bends, or mass press-formed parts?

SP Engineers Autotech offers end-to-end forming solutions backed by modern equipment and decades of expertise.

Get in touch today for pricing, plant visits, or technical consultations.